SELECTION OF THE YARNS

SUSTAINABILITY MEANS CAREFULNESS

Olmetex believes in the concept of sustainability not only as a valued ideal but also as a manufacturing process. With this in mind, it has implemented a photovoltaic system, installed a co-generator and adhered to a zero carbon footprint.

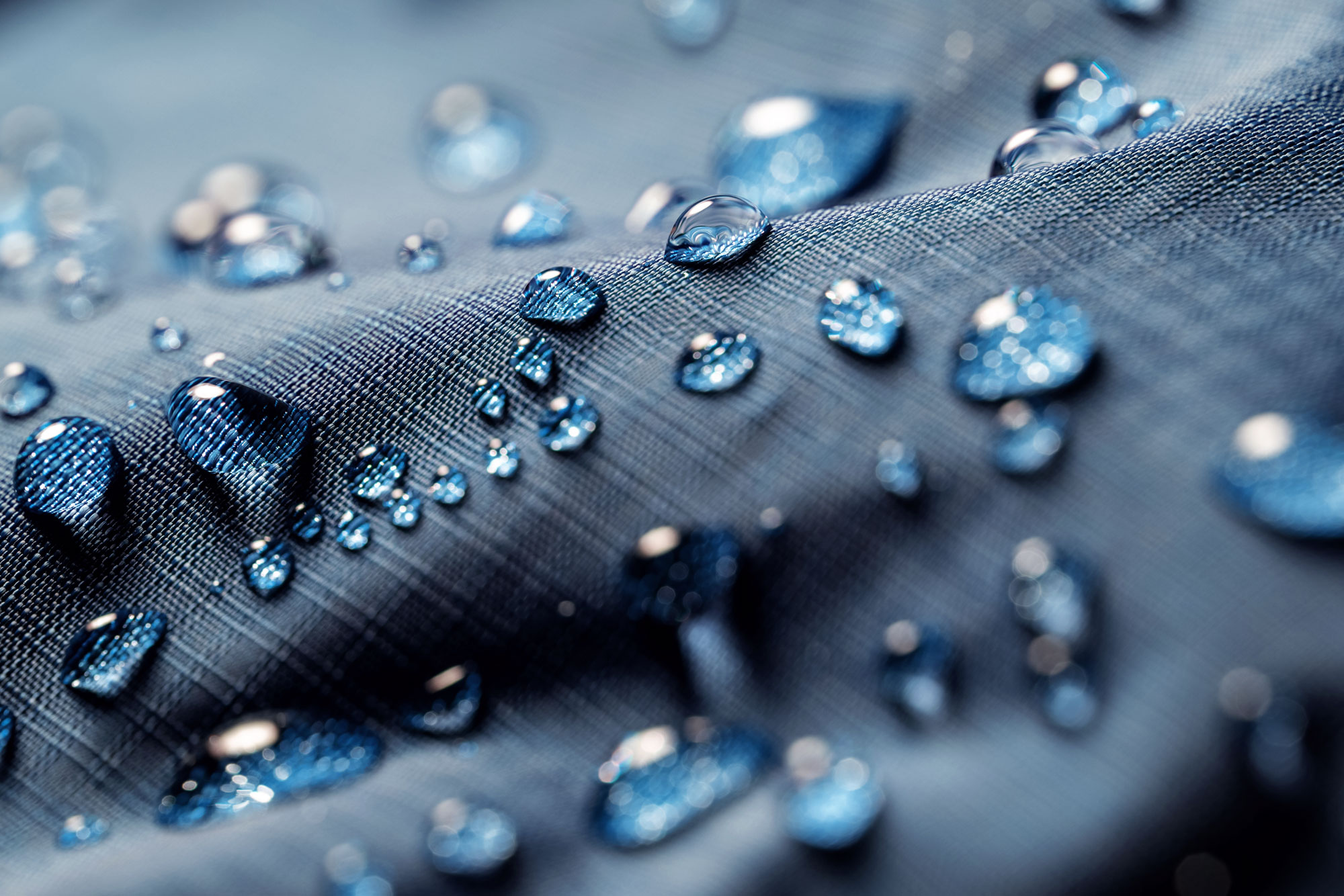

WE INCORPORATE PFC-FREE WATER-REPELLENT TREATMENTS

OUR COMPANY POLICY, BEING THAT OF WORKING WITHOUT THE USE OF FLUORO-ORGANIC COMPOUNDS (PFC-FREE), HAS LEAD TO INDISPUTABLE IMPROVEMENTS AT AN ENVIRONMENTAL LEVEL WHILST TRYING TO ENSURE THE SAME OUTCOME.

1440

ENERGY EFFICIENCY

PHOTOVOLTAIC PANELS

580

ENERGY SAVING

KW/H ENERGY EACH YEAR

200

KW/HCO-GENERATION PLANT

CO-GENERATION PLANTS ARE EFFICIENT ENERGY SYSTEMS THAT PRODUCE BOTH THERMAL AND ELECTRIC ENERGY SIMULTANEOUSLY FROM A SINGLE FUEL SOURCE. THEY OPTIMIZE THE USE OF ENERGY, REDUCE WASTE AND CO2 EMISSIONS, OFFERING A SUSTAINABLE AND ECONOMIC SOLUTION TO SATISFY ENERGY NEEDS IN AN INTELLIGENT AND ECOLOGICAL WAY IN THE INDUSTRIAL AND PUBLIC SECTOR ENVIRONMENTS.

70

%ENERGY AUTO-SUFFICIENCY

OUR SOLAR PANELS TOGETHER WITH OUR CO-GENERATION PLANT

ALLOWS US TO SELF-PRODUCE 70% OF OUR ENERGY NEEDS.

GREEN PRODUCTS

RECYCLED (POST or PRE CONSUMER) IN ORGANIC PA and PL

In the context of sustainable waste management, recycling represents a fundamental pillar for reducing environmental impact. Recycling waste, both pre-consumer and post-consumer, is vital in the circular economy, reducing the use of natural resources and landfill accumulation. Attention to organic waste, such as food waste, has grown: their recycling through composting or biogas production not only reduces waste in landfill but generates resources such as compost and renewable energy. In addition, certified sustainable finishes in the textile industry reduce environmental impact by ensuring the use of ecological methods such as the use of safe chemicals and water conservation. The adoption of these sustainable practices is fundamental for a responsible future and to promote a more circular and conscious economy.

CERTIFICATIONS

GREENLINE

NEW LIFE TO FABRICS

Thanks to our collaboration with GreenLine, an Italian partner that deals with the recovery and management of pre-consumer textile waste, we are able to transform it into a new regenerated resource.

1 RECOVERY

The recovery of textile waste takes place using authorized procedure and is divided by type and quality, with classifications for color, fineness and composition

2 TRACEABILITY

GreenLine allows complete traceability of the material through the use of technologies designed to monitor the path at every stage of recover

3 DISTRIBUTION

In order to avoid risks of counterfeiting, the mechanical shredding of delivered material is assured within an internal department thus making it unrecognizable

4 CIRCULARITY

The fibers obtained from previously frayed production is now available to be sold to brands, in order to close the circle of circularity in the fashion sector